Gas Dryers

Introduction

All air, gas, and liquids contain moisture in various amounts up to saturation, where just a slight change in temperature or pressure can cause water to condense or cause problems in process systems.

The amount of moisture in the air (humidity) can be expressed in two ways. The first is in grains per cubic foot. A grain is a unit of mass. When the amount of moisture in a volume of air is so described, it is called "absolute humidity."

When the relative humidity reaches 100%, the air is holding all the moisture it can and is saturated. Any drop in temperature will cause the moisture to condense out of the air. This point, where condensation begins, is called the "dew point" of that particular quantity of air under those conditions of absolute humidity and pressure.

Moisture in liquid systems is typically expressed in parts per million. Solvents, just like gases, have saturation limits; and designs take these limits into consideration.

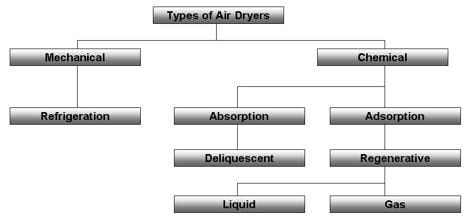

Process Systems, LLC can provide a full range of drying systems ranging from standard industrial designs to custom designed air, gas and liquid systems.

Following the links below will help in understanding the basics of air, gas and liquid dryers and hopefully aid in selecting the type of equipment you may need. We can help and guide in this process. We strive to be flexible in working with our clients to provide them with the best-suited system for their applications.

Relative humidity: Equals the ratio, expressed as a per cent of the weight of water vapor actually contained in a unit volume to the weight of water vapor which this same unit volume would contain if fully saturated at the same dry bulb temperature.

Absolute humidity: Equals actual weight of water vapor in the air at any given condition. Absolute humidity is usually expressed in grains per cubic foot or grains per pound of dry air (one grain equals 1/7000 pound).

Dew point: Equals the temperature of water vapor saturation of air, i.e., the temperature below which any further cooling would result in condensation of moisture from the air.

Water load doubles for every 10-degree rise in inlet temperature to an adsorption air dryer, which can double the size of the dryer.